The files below are available for download in Microsoft Word format. If you have a question about one of these documents, please contact us. We would be happy to help you.

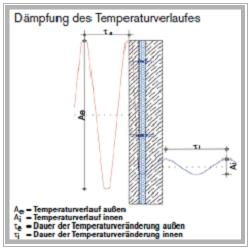

THERMOMASS as thermal storage element

The THERMOMASS system allows for the thermal storage capacity of concrete to be used to its fullest advantage. Heat or cold units are stored in the concrete mass of the internal layer of the panel and are released into the interior environment when the temperature decreases or increases. THERMOMASS thus enables HVAC (Heating, Ventilation, Air-Conditioning) equipment to operate at maximum efficiencywhile effectively controlling vapor transmission and minimizing the formation of condensation.

Using the Eichler method to calculate the performance of two sandwich panels for cold storage each with a thermal resistance of R = 6,5m²K/W, it shows that the THERMOMASS panel has a thermal absorption capacity of 5368 units which is subsequently released over 26 hours.

The metal face absorbs only 109 units which are dissipated within 10 hours.

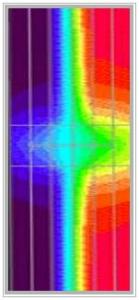

Bearing of thermal bridges

Insulatet sandwich – panel with traditionel steel – ties

Thermal transmission in insulated area: U=0.55 W/m²K

Thermal transmission around tie: U= 4.10 W/m²K

Average thermal transmission through panel: U= 1.58 W/m²K

Insulatet sandwich – panel with THERMOMASS – system

Thermal transmission in insulated area: U=0.55 W/m²K

Thermal transmission around conncetor: U= 1.86 W/m²K

Average thermal transmission through panel: U= 0.60 W/m²K

The average thermal transmission of a well insulated sandwich panel with steel ties is more than two and a half times greater than that of a panel with THERMOMASS connectors. The transmission rate ist sustantially worse in panels which are not insulated and have concrete seams with metal re-inforcements linking the layers. ONLY the THERMOMASS system ensures that 99 % of the design value of the thermal insulation performance of a building can be achieved.

System SW

- Precast – Ambient Applications (MS Word – 111 KB)

- Precast – Cooler Applications (MS Word – 125 KB)

- Precast – Freezer Applications (MS Word – 125 KB)

- Tilt-Up – Ambient Applications (MS Word – 112 KB)

- Tilt-Up – Cooler Applications (MS Word – 125 KB)

- Tilt-Up – Freezer Applications (MS Word – 131 KB)

System CC

- Precast Applications (MS Word – 100 KB)

- Tilt-Up Applications (MS Word – 96 KB)

System VW

- Cast-in-Place (MS Word – 61 KB)

System MP

- Modular Precast (MS Word – 117 KB)