Tensile strength

During form-stripping, lifting, transportation and installation, the sandwich panel undergoes high tensile stress. The aim of the test is to establish the capacity of the THERMOMASS connector to resist this stress. From the test it was clear that for a panel with an external wythe of 80 mm, the load per connectorwas in the range of 0,5 kN, allowing for the suction force caused by form-stripping. The connector easily passed, demonstrating a pull-out capacity of over 11,27 kN

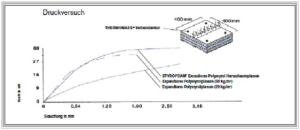

Compressive strength

If the panels are stored horizontally, they undergo compressive stress which is distributed over the thermo-insulating material and the connectors.

The test showed that, the panels using stiff insulation wall panels provided twice the resistance to compressive force, as panels usings expanded polystyrene foam, at an equal rate of deformation. The high compressive resistance of stiff insulation wall panels also causes the stress on the connector to be substantially reduced since it only needs to support 22 % of the load.

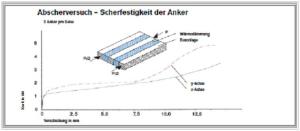

Shear strength

To verify the shear strength of the connector as a link between the two layers of concrete, the composite was subjected to a cyclical series of tests shown in the graph near. the results show that the shear strength of the connector – whether the axis is vertically or horizontally oriented – is 413 kg with a maximum deformation of about 18 mm. This shows that the orientation of the connector shaft is not a concern.